The Most Advanced and Affordable Next Generation Off-Grid Power is Here!

With the advancement in technology and the subsequent reduction in battery pricing, OFF-GRID POWER SYSTEMS have never been more attractive. It is no longer cost-prohibitive to set up an off-grid solar system and combine it with battery storage, securing reliable power for your home or business.

Solar My World has extensive experience delivering Off Grid power solutions for customers and have been connecting robust, inverter and battery systems for rural customers since 2009.

Relying on a single source of power is no longer the only option. With technology advancements in both batteries and inverters, off grid systems can be designed to operate seamlessly.

The revolutionary Deye Inverter allows the system to draw and dispatch power from multiple sources, including grid power, solar, wind, battery storage and on-site generation… Welcome the Super Hybrid Inverter.

Have peace of mind and be free from power interruptions with a safe and reliable off grid power supply for your property.

Relying on a single source of power via a grid connection is no longer the only viable option. Off grid power systems are now very affordable, they are the smart solution for those living in rural areas.

Industry Leading Technology

Stand-Alone Power Systems can range in size from 3.5kW -100kW and can utilise a variety of power sources to minimise cost and maximise your power reliability.

Deye hybrid inverter can deliver an uninterruptable power supply at an unrivalled price.

Talk to us Today to discuss how we can make Off Grid Power a reality for you 08 9274 6161.

A hybrid inverter is a highly efficient power management tool that allows you to hit your electricity consumption target by managing power from multiple energy sources.

A hybrid system generates power in the same way as a common grid to solar system, but uses special hybrid inverters and batteries to store energy for later use. This ability to store energy enables most hybrid systems to also operate as a back-up power supply in the same way as an Uninterruptable Power Supply or UPS.

Deye hybrid inverter is the most advanced inverter on the market and can do ALL of the following SIMULTANEOUSLY:

- Use solar energy for power consumption.

- Use wind energy for power consumption.

- Send excess solar/wind generation to battery to be stored.

- Pull power from batteries for power consumption if insufficient wind/solar.

- Pull power from diesel generator to supplement renewable energy.

- Restore battery reserves when excess power generated.

Solar myWorld uses Deye hybrid inverters

All of this is done seamlessly using the amazing SMARTS of Deye hybrid inverter. It can be used as a stand-alone inverter and available in either single or three phase. It can send power produced by solar and wind power into the batteries for storage and will only pull power from a diesel generator when the batteries are depleted to a certain level. Ensuring that you control what source of power is used first, delivering you the most efficient source of energy.

The off grid inverter has a convenient LCD display that can be configured to your requirements. The inverter is also WiFi capable which, once connected, provides remote monitoring and the ability to adjust the inverters functions to make the most of installed power generation and storage.

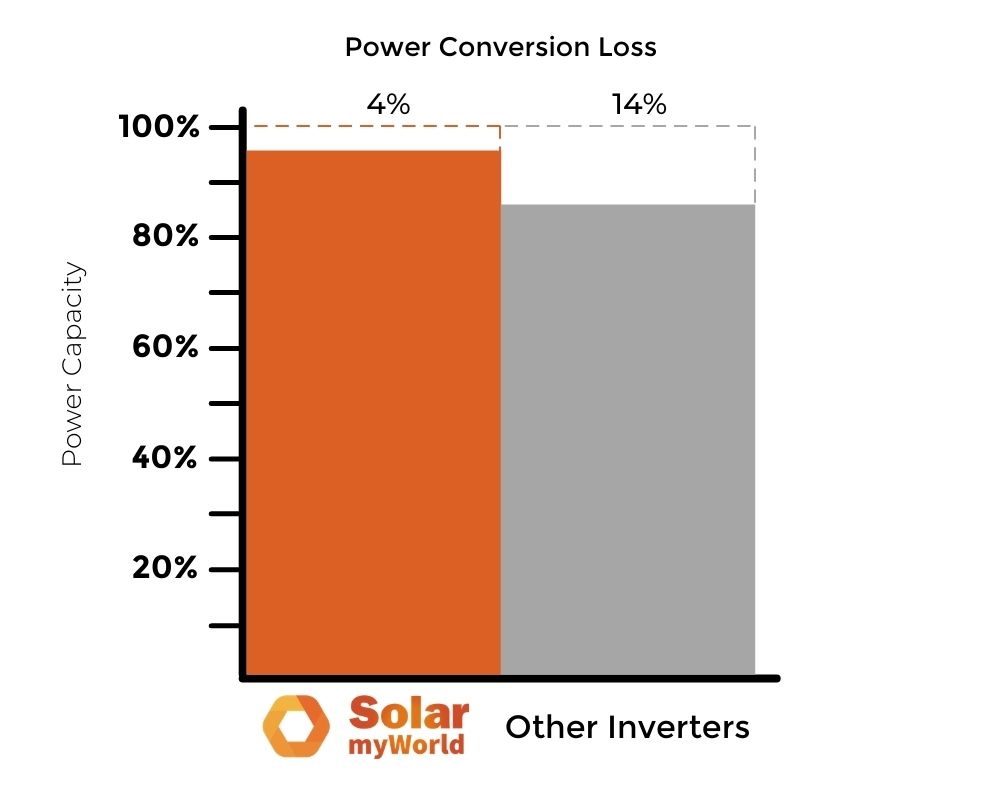

The Deye inverter is one of the most efficient on the market with only a 4% power conversion loss, most others on the market report around a 14% conversion loss.

Not only is Deye more efficient, but it is also less complicated and easier to install than traditional inverter systems.

Customers with an existing system can upgrade just their inverter to better maximise their existing system, ensuring all power sources are used at their cheapest price.

Power Up with Peace of Mind

From the smallest component through to building a Freedom Won (“FW”) containerised solution – with each step of the way, safety is paramount.

FW, an original equipment manufacturer, is compliant with industry best practices in terms of how to build and manage Battery Energy Storage Systems (BESS) in a safe environment and methodology.

In addition to these best practice guidelines, FW adheres to the ISO guidelines as set out in; ISO 9001: 2015, which is defined as the international standard that specifies requirements for a quality management system, ISO 14001: 2015, which specifies requirements for an effective environmental management system, and ISO 45001: 2018, which is the international standard for occupational health and safety.

We keep our employees safe as they design and assemble energy storage systems for home, business, commercial and industrial use – in turn contributing to a robust and safe renewable energy sector.

Every piece of the FW BESS is meticulously built with safety at the forefront of the design. Some of the components with advanced safety features are the LiFePO4 cells, BMS, copper busbars, wiring harnesses, circuit breakers, fuses, and the battery casing. FW also carefully selected and designed the packaging in which the batteries are transported.

The company’s principal range, the Freedom Won LiTE range, includes advanced safety features and has been leading the market with high-quality manufacturing and industry-leading performance.

LiFePO4 Cells:

According to BCG Research, Lithium Iron Phosphate (LiFeP04) consistently performs better than most other chemistries in terms of safety and battery lifespan. In 2009, FW was one of the earliest companies to develop the use case for LiFeP04 chemistry in the stationary storage sector.

FW experimented with LiFePO4 from the outset after carefully considering multiple aspects of the technology, specifically relating to the company’s stringent safety standards. The company found a cell technology partner in China – the country holds about 90% of the world’s LiFePO4 manufacturing capabilities.

FW has ensured that all our technology and design comply with the IEC 62619:2022 standard, which specifies design safety requirements and tests for the safe operation of secondary (rechargeable) lithium cells and batteries used in industrial applications, including stationary applications. “These cells get put through extensive testing to ensure that they can handle being dropped, crushed, pierced with a sharp object or short-circuited without catching fire,” says Antony English, the company’s co-founder.

“We looked into all other chemistries that were available at the time (2009) and by far lithium iron phosphate was (is) the safest, because it doesn’t spontaneously ignite if the cells get too hot; and right up front we only considered developing our products with this technology,” says English.

Our lithium batteries should never be dropped, as this could cause internal damage. However, during research and development, samples of FW batteries are drop tested according to applicable specifications, including being dropped at different angles. All FW batteries that were put through the drop test have continued to function normally.

BMS is on the ball:

The FW Battery Management System (BMS) records the number of cycles that the battery has delivered. It also measures and controls the voltages of each cell, internal battery temperatures, battery current, and pack voltage. It is critical for lithium cells to operate within specified voltage and temperature ranges to avoid irreparable cell damage.

While monitoring all functions within the battery, the BMS controls external components of the system, such as the inverter (through the CAN bus interface) by limiting the charge current and voltage, while also ensuring that the battery’s temperature is at a safe operating level. If the battery overheats and/or the voltage is too high or too low, the BMS can automatically stop the charge or discharge.

The FW BMS’s unique features have been developed and perfected over 15 years. The BMS can also calculate internal resistance of the cells and report abnormal resistance of busbars and connectors, long before any safety issues arise.

The BMS always monitors all safety critical features within the battery and will prevent an unsafe situation by either shutting down external devices through CAN bus or, if necessary, shutting itself down completely.

Copper Nickel-plated busbars – efficiency and reliability in one:

The innovation does not stop there. FW specifically designed the busbars to be larger than the industry norm. The busbar size ensures that there is minimal resistance, no hotspots, or heat build-up when running at high power.

As an electrical current conductor, the copper busbars within a FW battery are highly efficient. More so than most other metal conductors.

Nickel plating ensures that there is no oxidation of the conductor surface, which eliminates the risk of high-resistance connections developing over time.

Wired right:

The power cables or busbars are fastened to the cells with heavy duty studs or through laser welding, to reduce the risk of a hot connection because of being inadequately fastened.

The FW high voltage battery range also has fuses in series with the cells at multiple locations inside the battery. In case of impact on the battery or other mechanical damage causing an internal short circuit, the fuses will blow to limit the risk of further damage or danger to persons. Fuse isolators also ensure safety during an assembly at the factory.

Up and down cycling:

The FW batteries are designed to manage two 80% Depth of Discharge (DoD) cycles per day. If those cycles are less than 80% DoD, a pro rata calculation comes into effect. If a battery discharges from 100% to 20% State of Charge (SoC) followed by a charge to 100% – that is a full warranty cycle. This is an important consideration with South Africa’s loadshedding, as the country moves through the different loadshedding stages. A stage whereby the load is shed 4 times a day would mean that the same battery must do 4 half cycles per day. Should the battery operate through more cycles in a day, the temperature might rise to maximum levels (a situation that would be controlled safely by the BMS.). The FW container builds have internal cooling and utilise other mechanisms such as extraction to prevent overheating. “We also have insulation on the walls and ceiling to help maintain the equipment at a reasonable temperature in hot environments.”

Also, to ensure battery temperatures are controlled properly, the larger FW Commercial models include forced air fan cooling in the casing.

Circuit breakers:

The integral circuit breaker can handle high external short circuit currents; it prevents potential fires and allows the BMS to disconnect at any moment if needed.

The circuit breaker is an important aspect of the battery in terms of safety, as it too can turn off a battery that is malfunctioning.

“It is definitely one of the main distinguishing features of the FW LiTE, because the range offers very high performance, with DC rated breakers that can handle significant currents, both overload currents, and short circuit currents,” he added.

As a result of this feature, the battery could short-circuit externally and suffer no damage at all.

Comparatively, most other batteries on the market rely on MOSFETS (large power transistors) for current control. The FW circuit breakers also allow the BMS to disconnect the battery from the DC bus if a connected device does not respond to the CAN bus commands that aim to avoid an overcharge or discharge event.

Other batteries in the same class as the FW LiTE range also use contactors and rely on internal fuses; however, the limitation is that the contactor can still be damaged by a short circuit current whereas a LiTE range battery is still usable after a trip on a short circuit.

The FW circuit breaker is resettable and allows for the battery to be used again after an overload or external short circuit without replacing fuses or MOSFET boards.

Get in touch with us

Solar myWorld

Your home of Freedom Won Solar Battery Technology and Deye Inverter Technology in Western Australia

- Premium Quality Brands

- Residential Solar Systems

- Commercial Solar Specialists

- 3000+ Installations

- Local Western Australian Company

- 35+ Years in the solar industry